Optimizing the Supply Chain: The Power of APIs

Posted by: Deepak | October 04, 2024

Categories: supply chain optimization, API integration, supply chain management

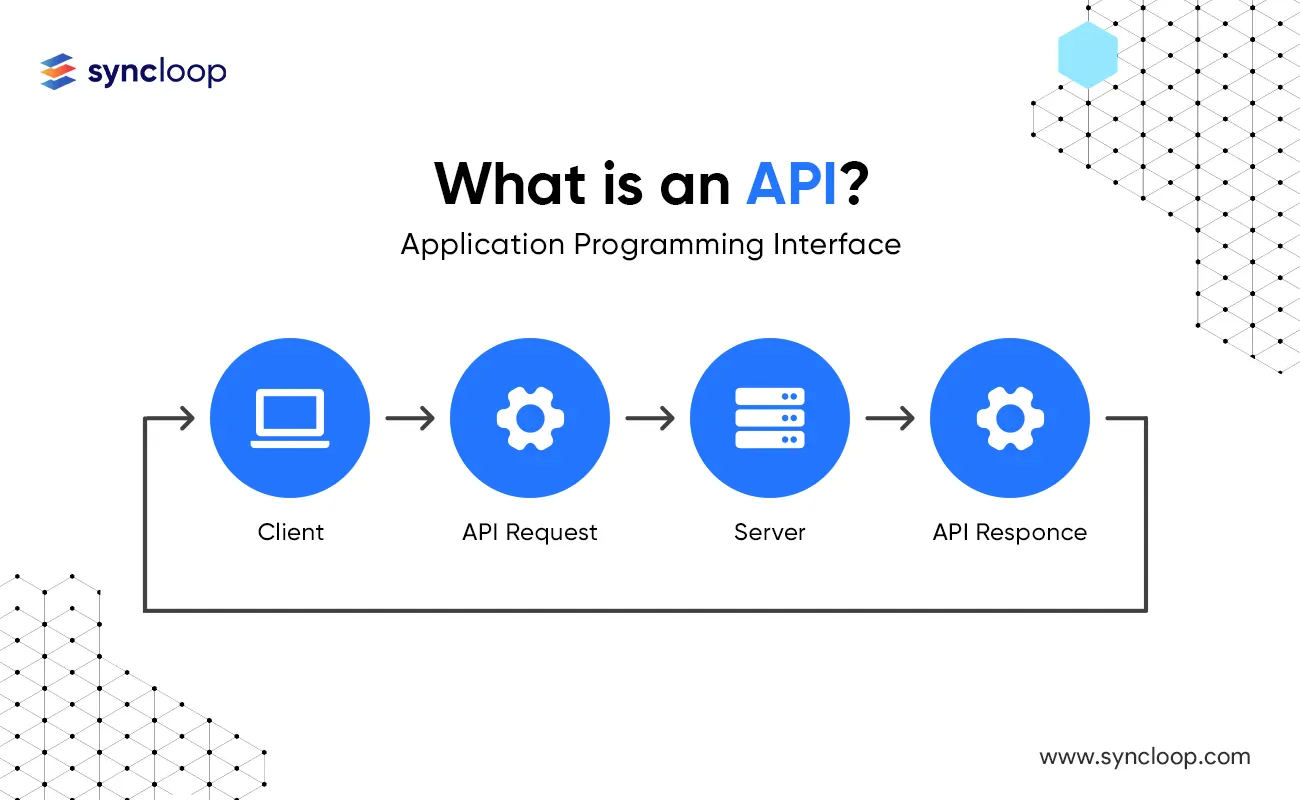

In today's globalized economy, efficient supply chain management is crucial for businesses to remain competitive. APIs (Application Programming Interfaces) play a pivotal role in enabling seamless integration and data exchange across the supply chain, driving optimization and improving overall efficiency. This blog explores how APIs can revolutionize supply chain operations, from procurement to delivery.

The Role of APIs in Supply Chain Optimization

APIs serve as the connective tissue between various systems and processes within the supply chain, enabling:

- Real-time Visibility: APIs provide real-time visibility into inventory levels, transportation schedules, and production processes, allowing businesses to make informed decisions and respond to disruptions proactively.

- Improved Collaboration: APIs facilitate collaboration between suppliers, manufacturers, distributors, and retailers, ensuring smooth communication and coordination throughout the supply chain.

- Automation: APIs can automate many manual processes, reducing errors, improving efficiency, and freeing up resources for strategic tasks.

- Data-Driven Decision Making: APIs enable the collection and analysis of data from various sources, providing valuable insights for optimizing operations and reducing costs.

Key Use Cases for APIs in Supply Chain Optimization

- Inventory Management: APIs can integrate with inventory management systems to track stock levels, automate reorder points, and optimize inventory allocation.

- Transportation and Logistics: APIs can connect with transportation management systems to optimize routes, track shipments, and manage freight costs.

- Procurement: APIs can enable automated procurement processes, streamlining vendor management, and ensuring timely delivery of materials.

- Quality Control: APIs can integrate with quality control systems to monitor product quality, identify defects, and track compliance with standards.

- Sustainability: APIs can be used to track and reduce the environmental impact of supply chains by monitoring carbon emissions, energy consumption, and waste generation.

Benefits of API-Driven Supply Chain Optimization

- Increased Efficiency: APIs can streamline processes, reduce manual labor, and minimize errors, leading to improved operational efficiency.

- Cost Reduction: By optimizing inventory management, transportation, and other supply chain activities, APIs can help reduce costs and improve profitability.

- Enhanced Visibility: APIs provide real-time visibility into supply chain operations, enabling businesses to identify and address potential issues proactively.

- Improved Customer Satisfaction: Optimized supply chains can lead to faster delivery times, reduced stockouts, and improved customer satisfaction.

- Sustainability: APIs can support sustainable supply chain practices by enabling data-driven decision-making and optimizing resource usage.

Technical Considerations for API Integration in Supply Chain

- Data Integration: Ensure seamless integration of data from various sources, including ERP systems, transportation management systems, and IoT devices.

- API Design: Design APIs that are well-documented, secure, and scalable to meet the specific needs of your supply chain.

- Security and Privacy: Implement robust security measures to protect sensitive data and prevent unauthorized access.

- Interoperability: Ensure compatibility between different systems and platforms to facilitate data exchange and integration.

Tools and Technologies for Supply Chain API Integration

- API Management Platforms: Platforms like Apigee, MuleSoft, and Kong can be used to manage and secure APIs.

- Integration Platforms: Tools like Zapier and Workato can facilitate integration between different systems and applications.

- IoT Platforms: IoT platforms can be used to connect devices and collect data for supply chain optimization.

- Data Analytics Tools: Tools like Tableau, Power BI, and Qlik can be used to analyze supply chain data and identify trends.

Challenges and Opportunities

- Data Quality: Ensuring the accuracy and reliability of data collected from various sources is essential for effective decision-making.

- Complexity: Integrating multiple systems and processes can be complex, requiring careful planning and execution.

- Security: Protecting sensitive supply chain data from cyber threats is crucial.

- Changing Business Environment: Supply chains are subject to disruptions and changes. APIs can help businesses adapt to these changes more effectively.

Conclusion

APIs are a powerful tool for optimizing supply chains, improving efficiency, and reducing costs. By leveraging APIs to integrate different systems, collect and analyze data, and automate processes, businesses can gain a competitive advantage and build more resilient supply chains.

Syncloop, a leading API development platform, can play a significant role in enabling businesses to create and manage APIs for supply chain optimization. Here's how Syncloop can be used:

- API Design and Development: Syncloop provides a collaborative platform for designing and developing APIs, ensuring consistency and efficiency in the API development process.

- API Management: Syncloop offers features for managing API traffic, security, and analytics, helping businesses monitor and optimize API performance.

- Integration with Other Systems: Syncloop can be integrated with various enterprise systems and applications, facilitating data exchange and automation across the supply chain.

- API Documentation and Testing: Syncloop provides tools for creating clear and comprehensive API documentation, as well as testing and debugging APIs to ensure they function as expected.

By utilizing Syncloop, businesses can streamline the development and management of APIs for supply chain optimization, leading to improved efficiency, reduced costs, and enhanced supply chain visibility.

Back to Blogs