Building APIs for Smart Factory Automation with Syncloop

This blog explores how Syncloop helps in building APIs tailored for smart factory automation, its unique features, and best practices to streamline the API development process.

The Role of APIs in Smart Factories

Smart factories rely on interconnected systems where devices, sensors, machines, and software communicate in real-time. APIs (Application Programming Interfaces) play a pivotal role in enabling this communication by acting as the bridge between disparate systems. They provide the framework for data exchange, ensuring that all components of the factory ecosystem work in harmony.

APIs in smart factories can facilitate:

- Machine-to-Machine Communication: Enabling machines to share operational data and trigger workflows.

- Data Analytics: Feeding real-time data to analytics platforms for insights into efficiency and predictive maintenance.

- Integration with Enterprise Systems: Connecting factory operations with ERP, CRM, and other business software.

- Remote Monitoring and Control: Allowing operators to monitor and control factory operations remotely.

Given the complexity and scalability of smart factory environments, robust and flexible APIs are essential.

Why Choose Syncloop for API Development?

Syncloop provides a comprehensive platform for building, deploying, and managing APIs, specifically tailored for smart factory use cases. Its features and benefits include:

- Ease of Use: Syncloop’s intuitive interface simplifies API development, making it accessible to developers of all skill levels.

- Dynamic Data Modeling: With built-in tools for dynamic data mapping and transformation, Syncloop makes it easy to manage complex data structures.

- Real-Time Processing: Syncloop supports real-time API calls, ensuring that data flows seamlessly across systems without delays.

- Scalability: The platform is designed to handle high transaction volumes, making it ideal for large-scale factory operations.

- Advanced Security: With support for OAuth 2.0, JWT tokens, and role-based access controls, Syncloop ensures that APIs are secure.

- Integration Capabilities: Syncloop enables seamless integration with IoT platforms, cloud services, and legacy systems.

Building APIs for Smart Factories Using Syncloop

Step 1: Define Requirements and Use Cases

Begin by understanding the specific needs of the smart factory. Identify key use cases such as:

- Connecting IoT devices to a centralized platform.

- Enabling predictive maintenance through real-time data analysis.

- Automating production workflows via machine communication.

Step 2: Create Data Models

Use Syncloop’s dynamic data modeling tools to define the structure of the data that APIs will handle. Map fields to ensure compatibility with IoT devices, machines, and software systems.

Step 3: Develop APIs

Leverage Syncloop’s no-code and low-code tools to build APIs rapidly. Use the platform’s built-in functions to define endpoints, data transformations, and control structures like Ifelse and Await.

Step 4: Test and Optimize

Syncloop offers robust testing tools that allow developers to simulate real-world scenarios. Test APIs for performance, scalability, and reliability to ensure seamless operations in the factory environment.

Step 5: Deploy and Monitor

Deploy APIs using Syncloop’s cloud-native capabilities. Use monitoring tools to track API performance and ensure uptime. Syncloop’s analytics dashboards provide insights into API usage, helping optimize processes further.

Key Features of Syncloop for Smart Factory Automation

- Workflow Automation Syncloop allows users to design and automate workflows across multiple systems. With visual tools for workflow creation, operators can automate tasks like inventory updates, machine scheduling, and quality control checks.

- IoT Device Integration Smart factories rely heavily on IoT devices for real-time data. Syncloop supports integration with IoT platforms, enabling seamless data collection and processing from sensors and connected machines.

- Predictive Maintenance APIs By integrating Syncloop APIs with AI-powered analytics tools, factories can predict equipment failures and schedule maintenance proactively, reducing downtime.

- Custom Control Structures Syncloop provides flexible control structures like Transformers and Redo, which are critical for managing complex logic in smart factory operations.

- Scalable API Gateway Syncloop includes a high-performance API gateway, capable of managing large numbers of API calls, ensuring reliability during peak loads.

Best Practices for Building APIs with Syncloop

- Prioritize Security: Implement strong authentication and encryption protocols to safeguard sensitive factory data.

- Use Versioning: Ensure backward compatibility by versioning APIs, especially when updating endpoints or functionalities.

- Leverage Event-Driven Architecture: Use Syncloop’s support for event-driven APIs to enable real-time responses to factory events, such as machine status changes or production anomalies.

- Document APIs Thoroughly: Provide clear and detailed documentation to ensure smooth adoption by development teams.

- Monitor and Optimize Continuously: Use analytics to monitor API performance and make iterative improvements to meet evolving factory requirements.

The Future of Smart Factory Automation with Syncloop

As smart factories continue to evolve, the need for reliable, scalable, and secure APIs will grow. Syncloop stands out as a platform that not only meets these needs but also empowers developers to innovate. By leveraging Syncloop’s features, smart factories can unlock new levels of efficiency, adaptability, and resilience in their operations.

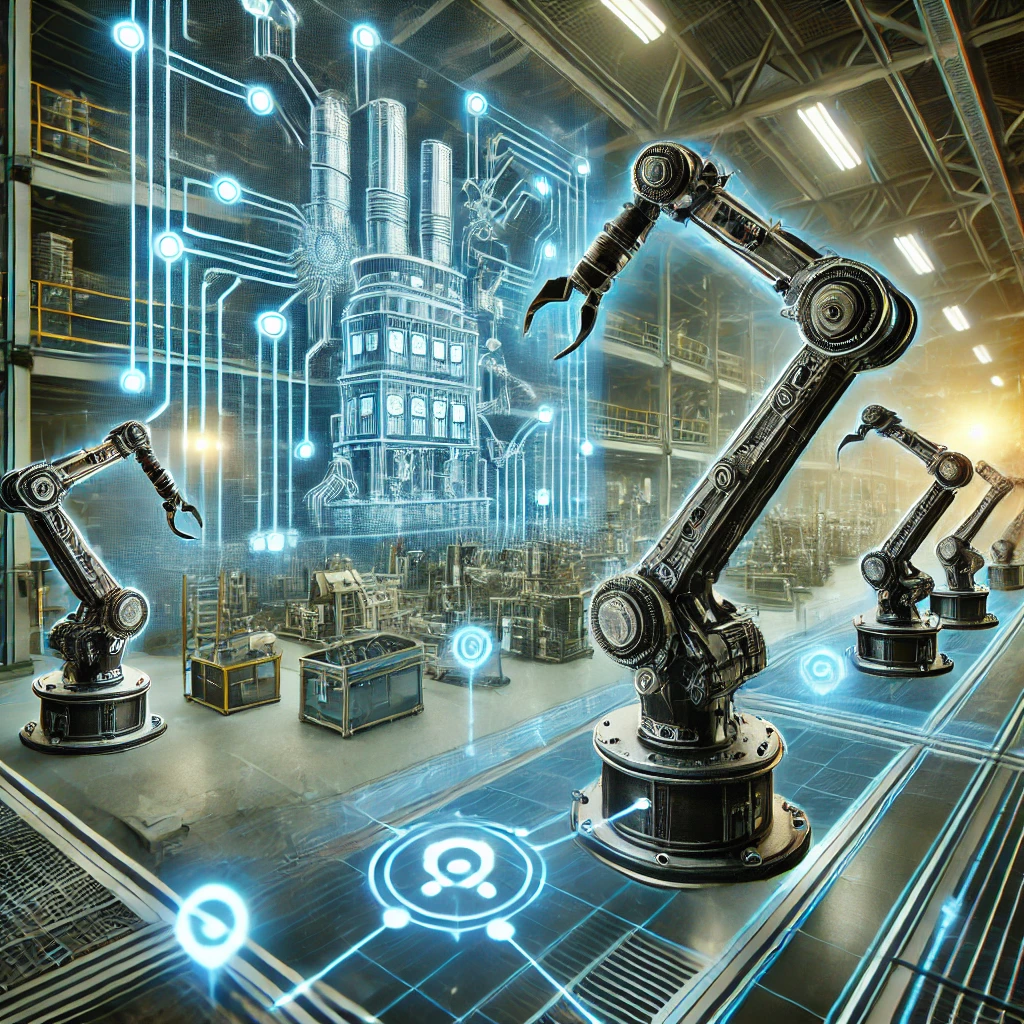

Image Description

An illustration of a smart factory with interconnected machines, IoT sensors, and a central dashboard. The image highlights data flow and automation enabled by APIs, with Syncloop’s logo subtly featured in the background.

Back to Blogs